About Our Eucalyptus Blue Mallee Essential Oil

This traditional eucalyptus essential oil is great for head colds, flu and is known for relieving tired/aching muscles.

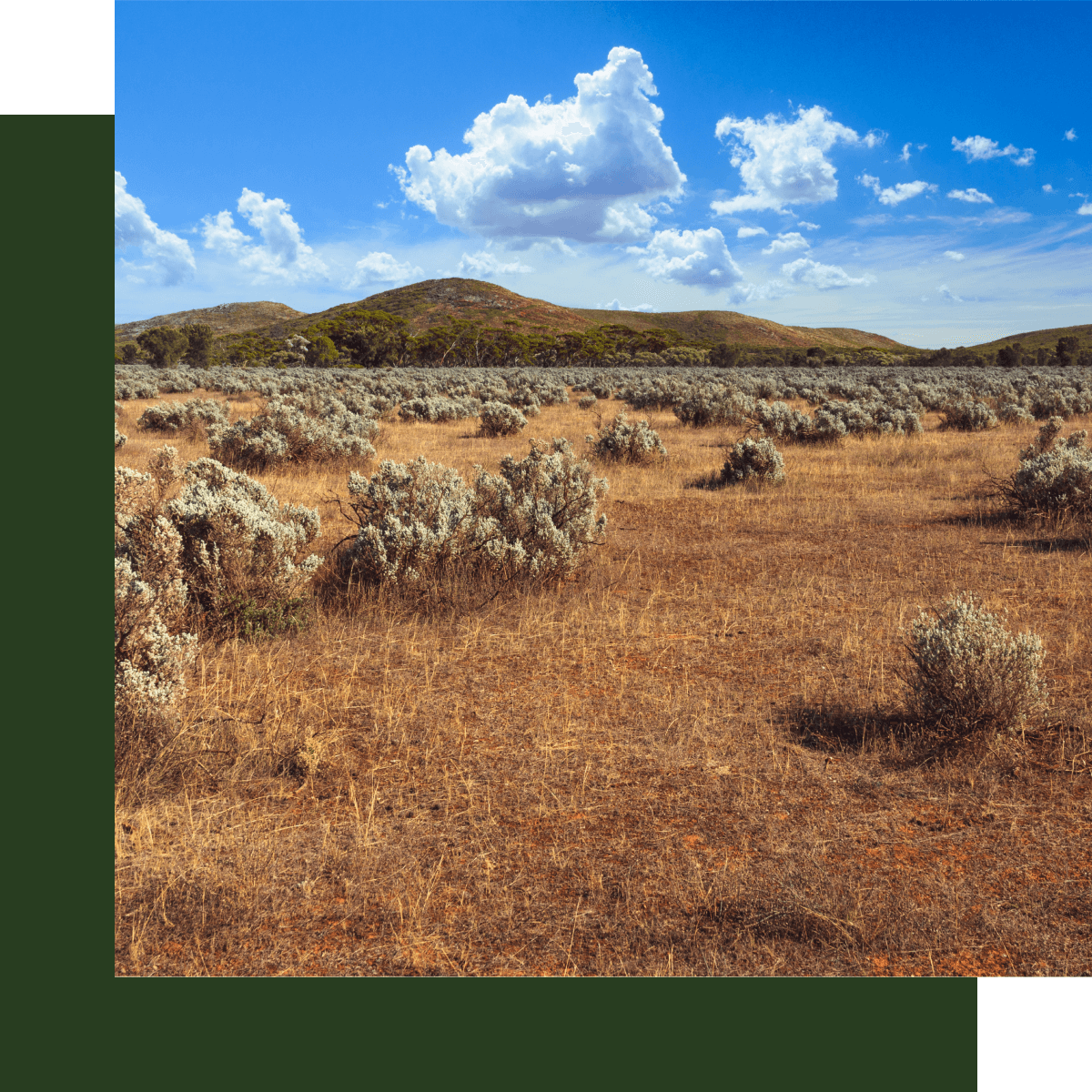

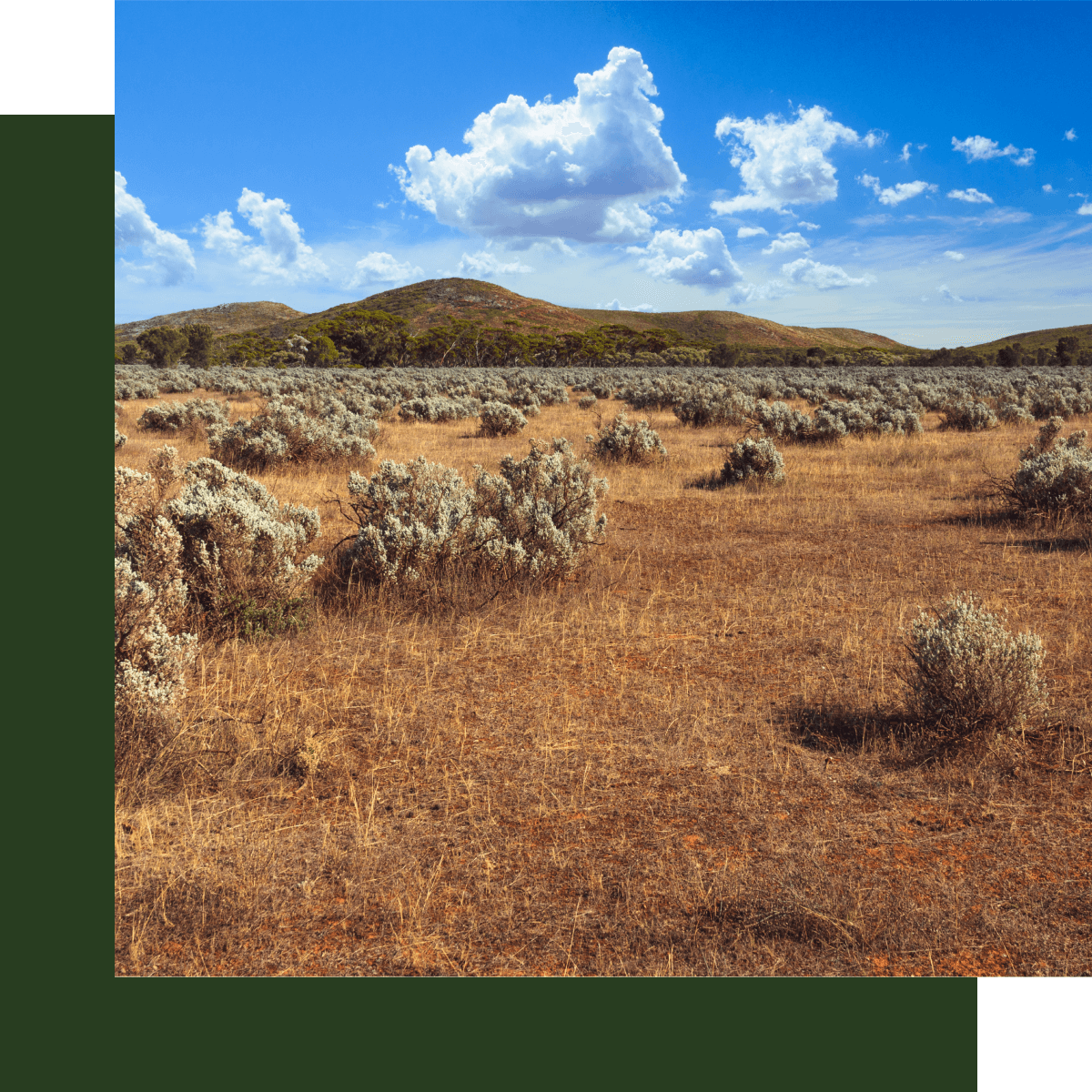

Eucalyptus Blue Mallee Essential Oil helps purify the air with antibacterial properties. The production of this amazing essential oil was started on this farm in South Australia. Production is now managed by the farm owners, who've had it for the last 12 years.

History & Traditional Uses

The eucalyptus oil industry is an important and colourful part of Australia’s history. Eucalyptus polybractea, commonly known as the blue-leaved mallee or simply blue mallee, is a species of mallee that is endemic to south-eastern Australia. Research states Eucalyptus was found in 1852 in Victoria and became well established by the turn of the century, when Eucalyptus oil became a major Australian export overseas.

Indigenous people made use of this oil for cuts by wrapping the leaves around the wound. The leaves were boiled or smoked on a fire and the oil vapours inhaled for treating colds and flus.

Agriculture, Harvesting & Distilling

Mallee trees have an extensive root system that lies just under the surface of the soil. This acts as a defensive system for fire and as a reservoir for moisture and nutrients. This is essential for the tree in what is a very low nutrient soil system.

Blue Mallee trees are typically shorter trees and grow to around 8 metres. The tree tends to flower in autumn and early winter. Characterised by a cool wet season, which charges the soil with virtually all the moisture that the crops will receive prior to harvest, followed by a warm dry season.

In steam distillation, the biomass is directly contacted with steam; the techniques are considered user-friendly, scale up easily and environmentally-friendly. A solid fuel boiler is used which is fired by spent biomass (eucalyptus leaf and twig after distillation). The boiler produces 500kg of steam per hour at 100 to 120 degrees. Steam generated in a boiler is passed through the bed, so that the essential oil in biomass is leached out to the steam. To prevent the degradation of oil quality, the steam temperature is controlled between 90 ºC and 100ºC. Then, the steam-oil mixture is passed through a water condenser and the products are separated in a decanter, resulting in 100% pure essential oil.